Timber frame base for log cabins

I’ve been pondering this post and am slightly reluctant to write it as I am NOT a structural engineer. I have lots of experience with timber but I am not at all qualified to give technical advice and specifications, so please read this post in the spirit it is meant.

You have no come back on me personally if anything goes wrong, the design of this is completely down to you but I will give some advice and ideas based on my experience.

Since I highlighted this type of base in my log cabin base requirements page we get lots of questions on my very favourite base:

The timber frame base for log cabins.

What I love about a timber frame base is that:

It can be moved.

It’s truly a temporary structure which is great in certain circumstances.

It allows air flow and therefore the timber will never rot even if it’s not treated.

It’s very easy to create a level base in very unlevel areas.

It’s a cheap solution in inaccessible areas for concrete.

Cheap overall.

If subsidence occurs you can simply jack up the area concerned and re-pin.

A good system when flooding occurs naturally and does not affect it’s environment.

No doubt you’ve done some research on all the types of bases you can use. You’ll have perhaps come across various types of pads, plastic grills, jack type things, easy bases, there’s all sorts of gadgetry out there. If concrete or paving slabs is not a solution for you you can’t beat good ol’ wood over all the gadgets and alternatives there are.

Stick to wood

My advice is to stick with wood and don’t waste your money on the gadgets, you know where you are with a good lump of wood:

It’s relatively cheap when compared to other ‘gadgets’

If treated and looked after it lasts forever (ish)

If anything needs replacing you can do so easily.

If you need more it’s readily available.

A timber frame used as a base for a log cabin does not need fancy timber, rough sawn from your local builder merchant is perfectly adequate but it would ideally be pressure treated (tanalised – More information on tanalised timber)

What size timber to use?

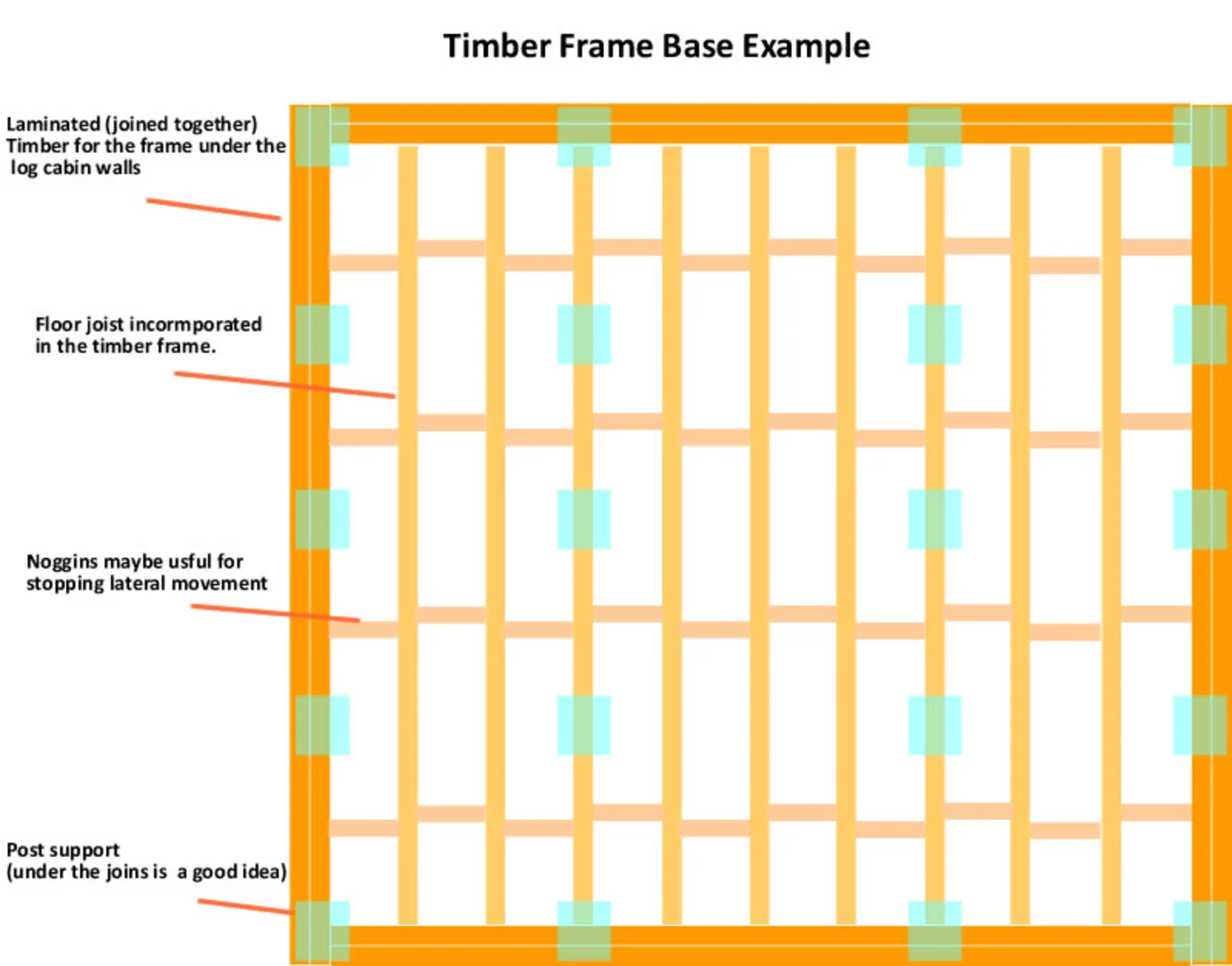

I’m often asked what size timber to use, as I mentioned, I’m not a qualified engineer, don’t necessarily go by my advice but I like big, chunky and manly bits of wood. Something like 150mm x 50mm and then laminated and used under every log forming 150mm x 100mm, sometimes for bigger buildings even bigger.

I don’t have structural calculations, this is all touch and feel. I think anyone with any slight experience can look at a piece of timber and decide if it’s strong enough.

Here’s a base I was involved in:

This base went on to support one of our biggest 70mm log cabins: The Edelweiss 70mm log cabin You can see here how we have joined wood together to form the main frame. Sometimes you can do it in two sections, two rectangles and then join them together. Notice also the posts we are using, I like big and these are nice big lumps of timber.

Alternatively though you can also laminate your timber to make these. I prefer to see the support posts directly under a join as you know it is always going to be supported if screws or bolts fail.

This was another one I took part in. This example was not actually for a log cabin but the same principle applies:

Notice how the post supports are under the joins in the corner and middle. This one was made in two rectangles and joined together in the center. As your support legs get longer lateral bracing is a good thing to consider.

Supporting your timber frame base

I’ve tried a few things in the past and looked at a few more. I’ve had a go with the plastic grids you can get but I still don’t really see the point of them apart from they’re a bit lighter but I worry about the longevity of them. Great in a greenhouse but I still think you can’t beat a nice solid slab on a bed of sand, or sand and cement.

Make sure though of the stability of the ground underneath as you don’t really want subsidence in years to come.

A suggestion on a good timber framed base

This is just a suggestion on how I would build a timber frame base for your log cabin, it’s not gospel, it may be wrong, remember I’m not a structural engineer or a qualified landscaper so you need to design your own way of doing it. My ideas might help though.

This is just an example and my personal thoughts (you may have your own) on how to make a good timber frame base for your log cabin.

Richard's point

I’m using a standard size timber, all of the same size, maybe 150mm x 50mm (6″ x 2″)

Laminated around the perimeter of the cabin walls for strength. Screwing / bolting with coach bolts the timber together every 1m or so. For bigger buildings I might use thicker timber. Every wall will have this support under it.

I’m using chunky support posts under the joints. Either use big 12cm timber posts like we supply or consider laminating.

You may want to consider, depending on the size of your building, using noggins to stop lateral movements of the joists

Incorporate your floor joists within the timber frame base. Our floor packs for log cabins are designed only for a flat and level base such as concrete or paving slabs. House joists measure 300mm apart. It’s a good idea to use this measurement in your log cabin floor. Heavier items may need them closer.

You will NOT need to use foundation beams under the first log. The sole purpose of them is to keep the first log away from ground contact. You already accomplish this with a timber frame base for your log cabin. With joists incorporated in the frame this will also give a better finish and everything will be at the same level.

The outside of the timber frame should be identical to the footprint listed with every log cabin to properly support the log. Bear in mind the log thickness of your building though as it’s good to have a lip on the inside of at least 25mm for the floor to sit on.

If you feel like being clever, bring the frame in by 2-5mm from the footprint. This will then set the frame in slightly giving a drip for the logs and you can be sure water will never sit against the first log

Consider using joist hangers for the floor joists as these will be easier and quicker.

If your post supports are above 300mm I would start to consider lateral supports to stop any movement.

Consider your spacing of posts support. I like to support every 1.50m depending on the building and thickness of timber.

Consider using Weed Control Matting under the base

That’s pretty much it as far as I’m going to help you.

Your turn

Hopefully you now have some ideas of your own. The principle is quite simple. Make a frame for your log cabin to sit on and make sure it does not subside and support the walls. Above all make sure it is properly, 100% level! Oh and jump on your frame before installation – this is my technical test to check whether it will work 🙂

Examples of Timber Frame Bases

Here’s some examples of what others have done, all of them work. It’s up to you what information or ideas you take from this post ……

Conclusion

This post is not official advice, it’s nothing to do with Tuin or Tuindeco, all mine and I often get things wrong (so my wife says) take from it what you can but a timber frame base for your log cabin can get you out of a lot of problems and expense.

I hope you have some ideas? If you do please share them.

To make leveling the base we do have a nice product. It’s not a bad price either and you can level between 30mm and 140mm using a combination of two units click on the picture for more details:

About the author: Richard

Meet Richard, a dedicated professional with a rich history at Tuin, contributing 25 years of experience within the garden timber industry. With an expertise in garden buildings. From design, manufacturing and installation for a range of timber buildings. Sheds to log cabins and all the way up to timber framed houses. In his time he had worked with experts all over europe, and also included his own personal experience of installing and testing Garden Buildings from a range of companies, models and sizes. You will find a majority of his blogs to include expert installation advice for your Log Cabin. Information on how timber reacts to different environments and the best way to preserve your garden buildings.