Log cuts in log cabins

Log Cuts in Log Cabins, This short article is the second in my timber series which tries to explain the types of timber we can use in log cabins. In this post I will try to explain how we can muck about with the timber to give you a really good price. But is it really good quality? Do you really want it?

The first in the series is here: Types of Timber in your Log Cabin

Timber mills

I’ve already spoken about Spruce and Pine and their differences, now we can look at the actual log.

Logs arriving at the mill

When the felled logs arrive at the mill, an assessment is carried out. That finds the best way to cut them for whatever uses have been specified. There are numerous different cuts for various reasons. It not simply a case of slicing them up. Wood is very expensive and the various parts of a log are worth varying amounts of money.

Parts of a log

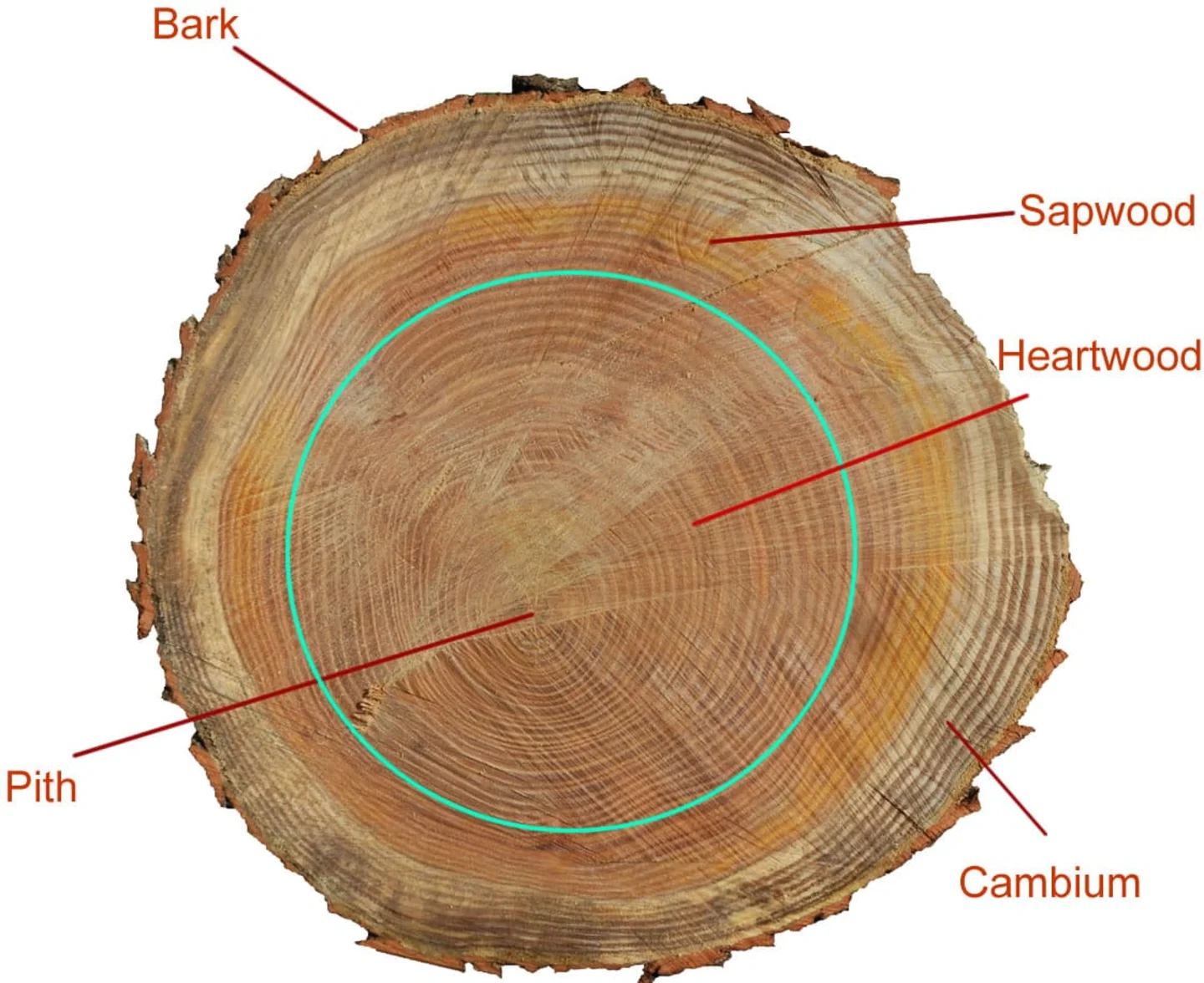

So lets look at this log:

Parts of a tree trunk

There’s a few parts to it, each has it’s own properties and of course monetary value. It makes sense that the most valued part of the tree is the heartwood, this is the strongest part. It’s far more dense, it has less knots in it and is where all the full ‘goodness’ of the wood is.

This is the bit we like and are most interested in. This is the part that we make all of the posts from in the gazebos so we can be sure of the full strength, of course it does cause a few problems sometimes. Please see this post about the inherent problems of using this heartwood that sometimes a customer may see as a defect: Crack and splits in timber. However if we didn’t use it, and we used a different section and make a higher profit, your gazebo would not be half as strong. We’d be laughing to the bank but would you want that?

The heartwood is also the part Tuindeco will use for the log cabins but more on that a little later, lets keep looking at the log.

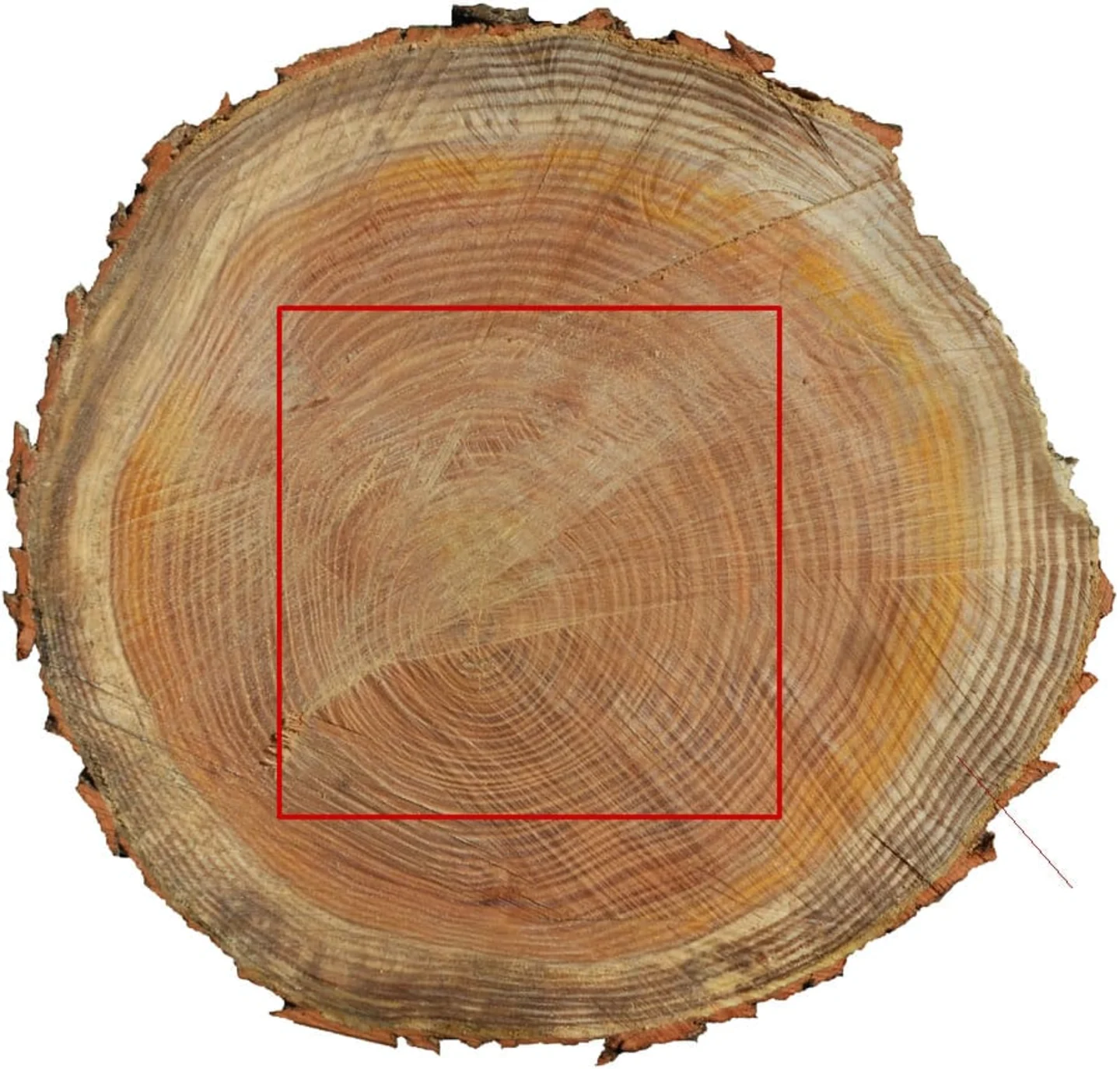

Best bit of the log

Lets look at our log again, we now know that the best and most expensive part is going to be the heartwood. So as a mill we might look at this log and think to ourselves how we can cut it to provide the strongest piece and of course make the most money giving the highest grade of timber. Perhaps we’ll cut this from it:

Best and strongest part of a tree trunk for logs

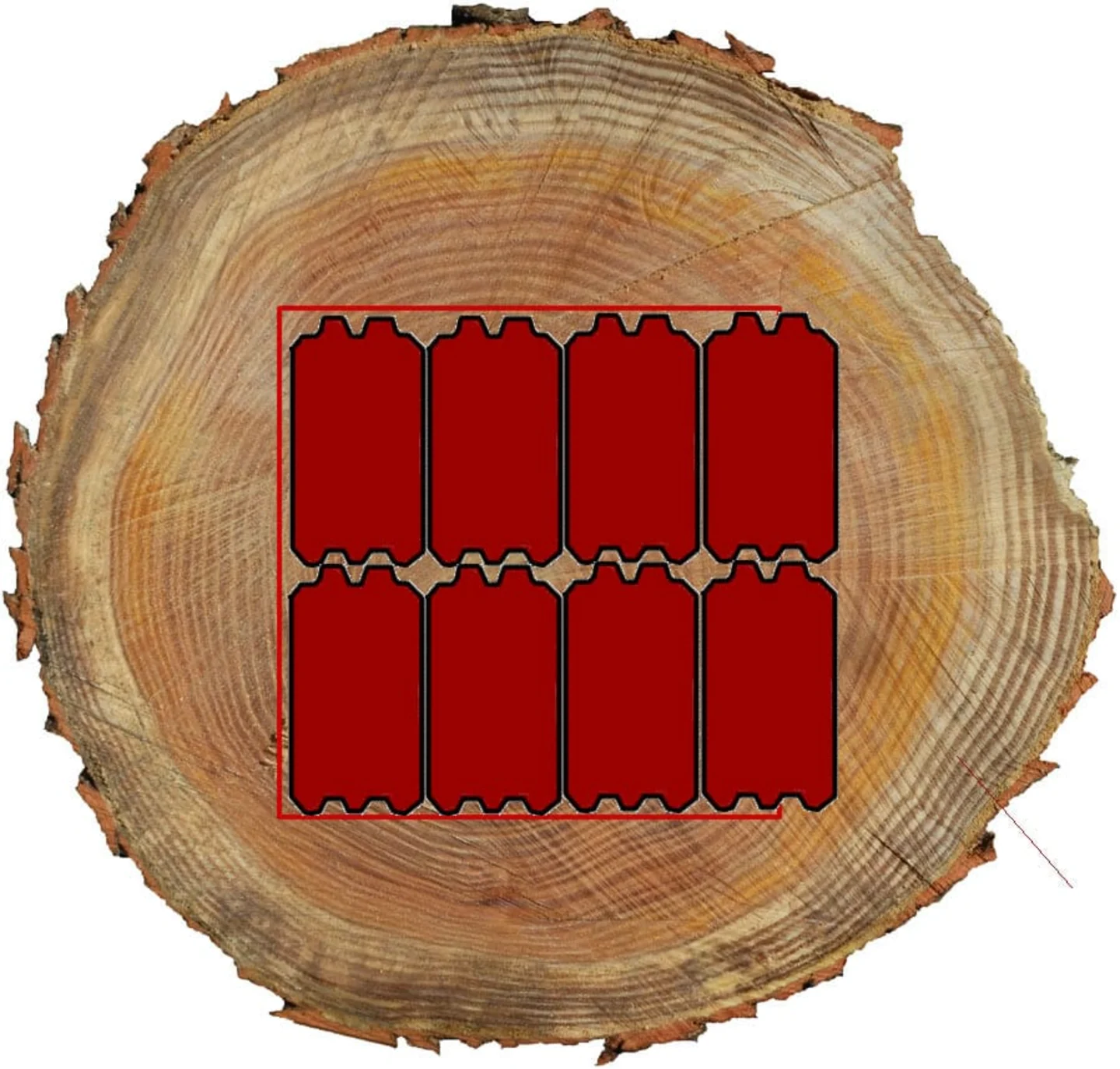

With this we can take the most expensive piece and sell it at a premium and meet the Swedish Timber Grade of I – IV. We still have the rest of the log to play with and we can cut it up for all sorts of different uses meeting lower Swedish timber grades, maybe we could cut it like this:

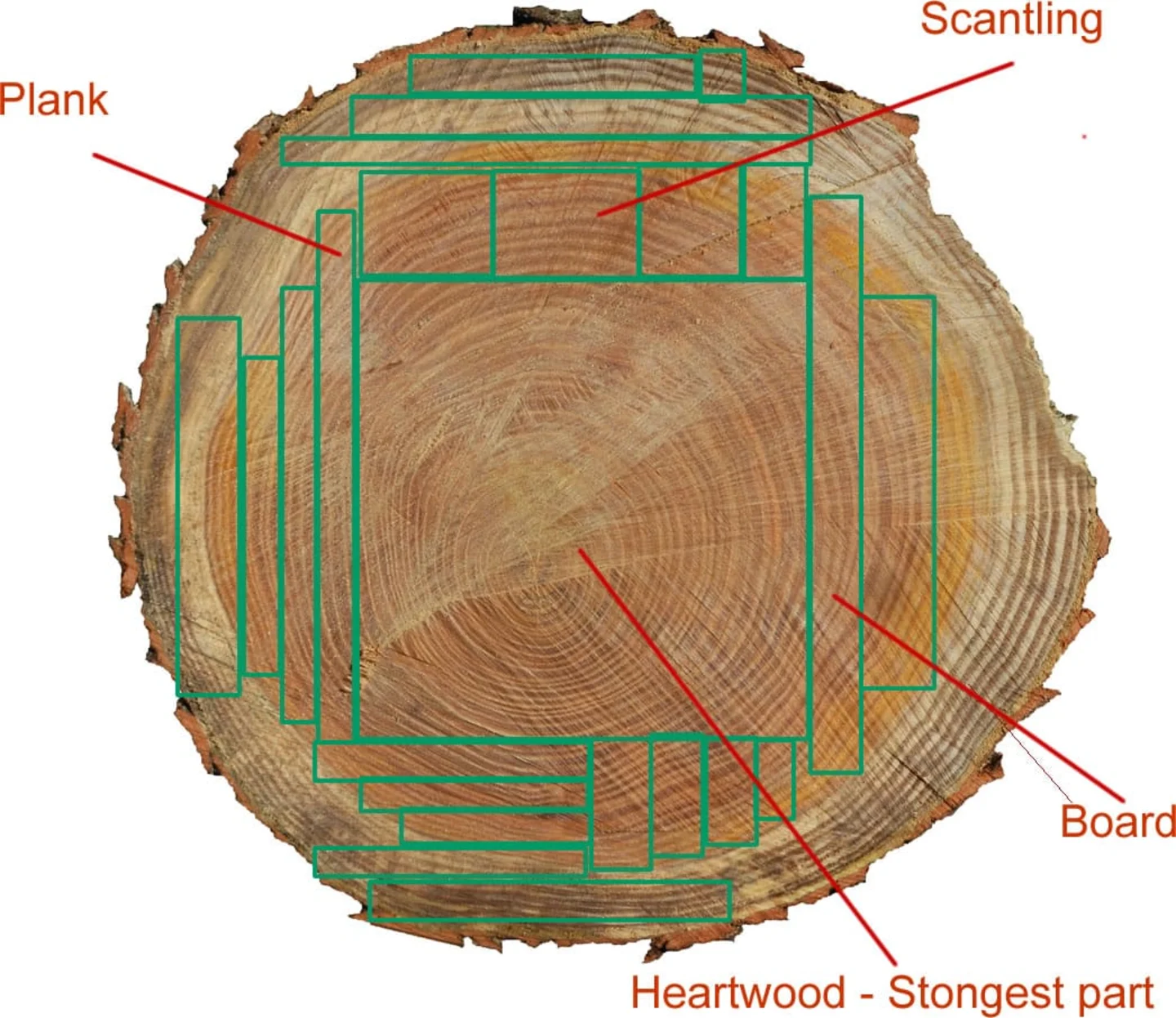

Cuts you could possibly apply to a log

There’s lots of technical terms we can use, Flitches, Deck, Board Scantlings etc. I’ll not bore you even more than maybe I am now.

Basically it means we’re cutting up the log to make the very best use of it. We’re cutting it to grades and to what we can get for it according to the buyers requirements and maybe their budget.

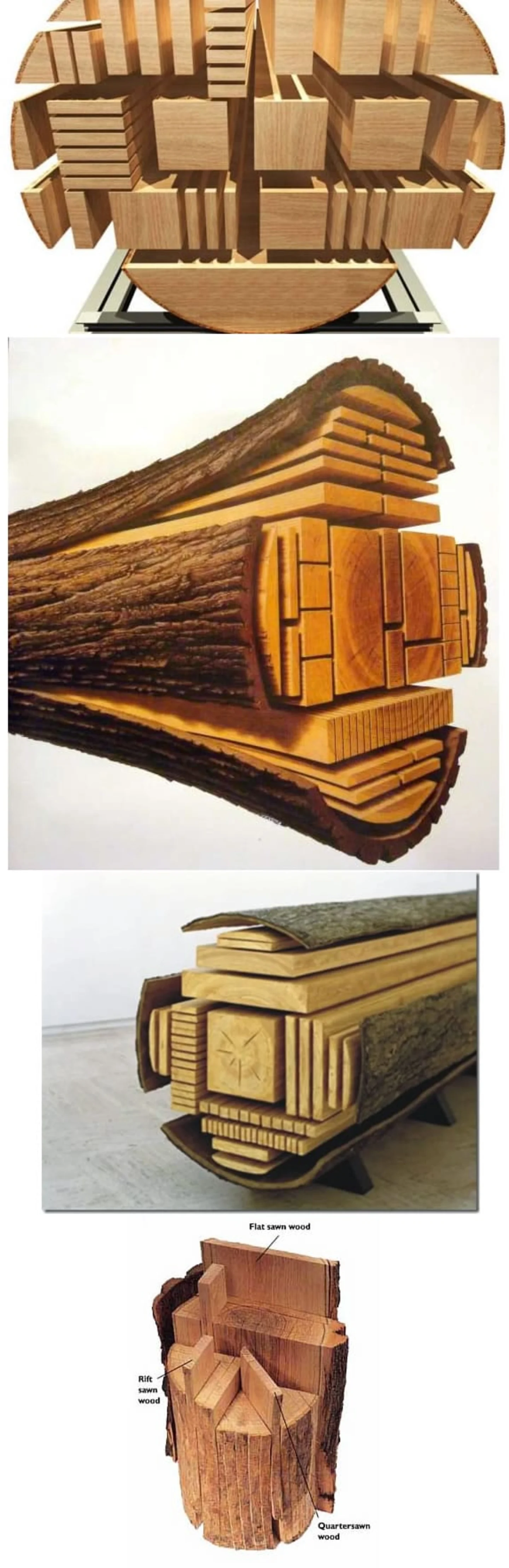

I found these images very interesting on the various cuts that can be found within a tree for various purposes:

Various types of cuts available from a log

As you can see there are lots of different ways to cut it, it gets even more technical and in another post I can blabber away about how we cut it to ensure knots do not fall out (Re-Sawn). Or how we ensure the very heart is cut to remain totally straight throughout the length of the final log cabin log.

Log cabin differences

I’ve seen another supplier of log cabins talk about differences in various log cabins. They are however completely missing the point. Double glazing and locks, roofing materials and sizes really are not the point when it comes to the buildings.

The ONLY thing that matters is the type of timber used, the quality of it, where it is from and where it is cut from within a log. And of course the moisture content (another post will deal with this) Moisture content makes a HUGE difference to the timber used in a log cabin.

Windows and doors, fancy locks, glazing, roofing etc is very superfluous and will not have any bearing on the quality or longevity. The timber is the important part and in my opinion the only part to worry about when you are researching or buying a log cabin.

How do you cut joints for a log cabin

OK, lets assume you’re out to buy a log cabin, you’ve got cash to spend and maybe you can go direct to the timber mills and maybe even you can go direct to the factory. First I suspect you want the best timber, we’ve already talked about timber before: Types of Timber in a log cabin. and maybe you can get to the forest to select the best trees in the right location.

BUT now you can make it even cheaper and really get the price to where you want it. Maybe you are a UK supplier out to blast the market with you super duper best price log cabin

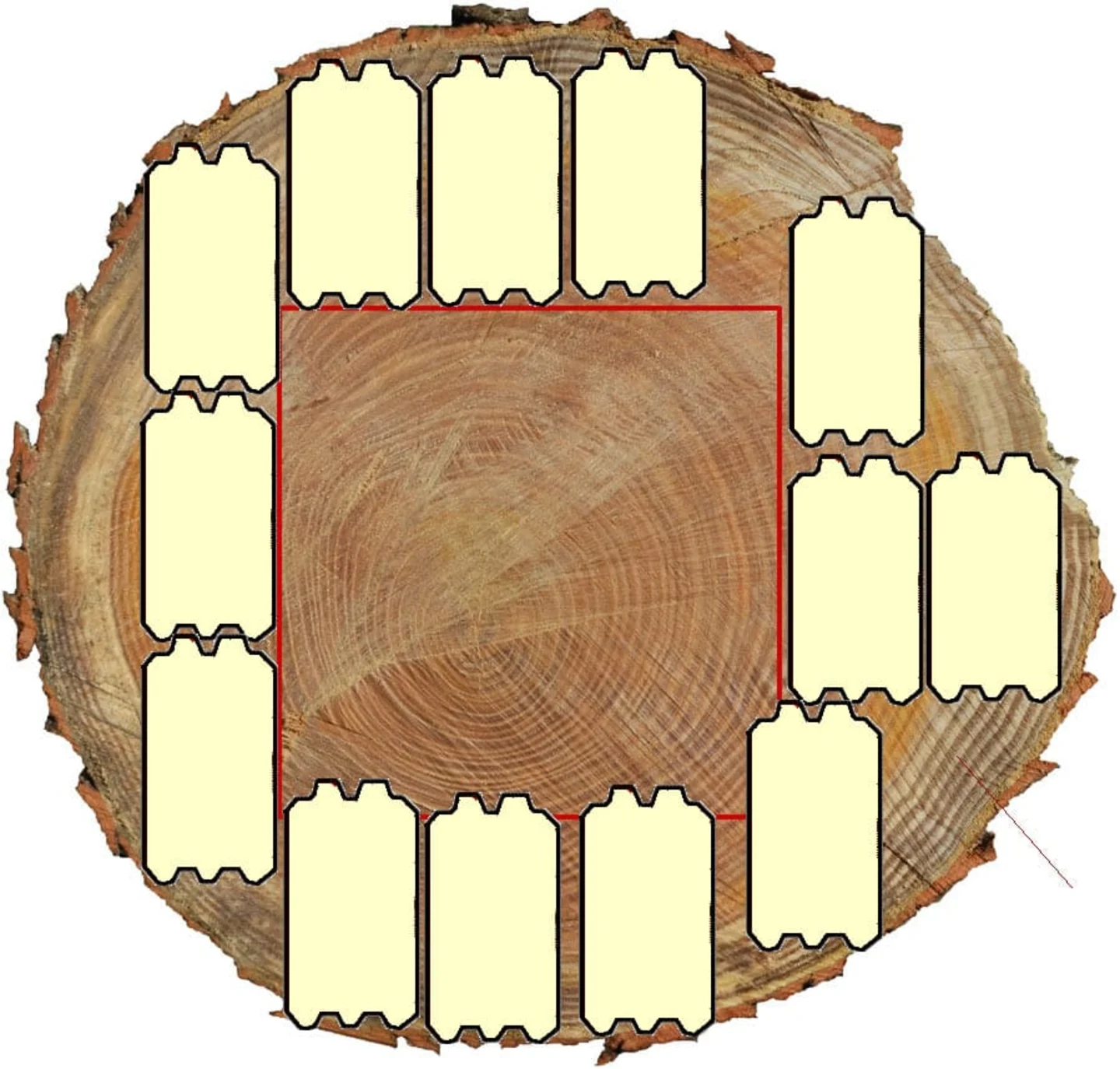

So why not use these cuts from a log and ask them to make the logs from them? This would be super cheap, probably about 20 – 40% cheaper :

Logs you could take from a tree trunk

Blimey, you’d make a killing! Your Log cabin would be way cheaper than anyone else, You’d sell LOADS

This is exactly what some suppliers will do. The outside of a tree is about 20% less weight than the inside. It makes for a cheaper building and certainly looks right on paper. You can even quote a Swedish log quality (above V but would you know the difference?). Kiln dried, really super duper! All the customers would think they have the UK’s best deal! WOOHOO!

By the way, I heard a quote recently from a very good friend in the industry. He said: “I can make a log cabin to any price you want. You want cheap? You will sell hundreds in the first few weeks but never answer the phone again!”

We would like to answer the phone this year and next and the year after……

But really what do you want? If you were at the mill and knew all of the above what would you really want? Maybe this cut or are you not that bothered?

Inside cuts for a log cabin

Timber series

Following on from this I intend to write a short series on timber in log cabins. You really wouldn’t believe the differences and the ways we can play with wood to get to the prices you the consumer wants but. Do you really want it in the long term?

The first in the series is here: Types of Timber in your Log Cabin

The following will be added to this blog over time:

Moisture content in timber, machining and the impact of the content.

Timber calculation to cut costs. You can work out yourself and see where you maybe opting for a bargain while adding to a companies profits.

More expansion information for log cabins.

The pitfalls of thinner logs, barge-boards, windows and doors.

Drying processes – kiln dried versus natural drying.