Ongoing log cabin maintenance: How to keep your cabin in top condition

Your log cabin is more than just a garden building. It’s a long-term investment, your personal retreat and often a multifunctional space for work, leisure or storage. Whether you’re using your log cabin as a home gym, garden pub or garden office, your log cabin faces constant exposure to the elements, changing temperatures and natural movement in the timber.

This exposure means that ongoing maintenance to keep your log cabin fully functional and looking its best is essential. Log cabins are designed to be durable, but no timber building is 100% maintenance free. By following a few simple maintenance tips every year, you’ll prevent costly repairs, extend the lifespan of your log cabin and keep it looking and performing its best.

In this guide, we’ll provide you with tips on the most important aspects of log cabin maintenance, from treating walls and adjusting doors to managing moisture and protecting your roof. Whether you’ve just installed your log cabin or you’ve had one for years, these tips will help you keep your garden building in top condition throughout its lifetime.

Six key areas of log cabin maintenance

To help you understand which parts of your log cabin require regular maintenance, we will break the log cabin down into five areas:

The base

Foundation beams

Walls

Doors and windows

Roof

1. Log cabin base maintenance

The base of your log cabin is one of the most important structural elements. It supports the entire building, ensures level alignment and helps to prevent future issues such as warping, door misalignment or cracking.

A well-constructed base should last for decades, with minimal maintenance required. However, we recommend inspecting it occasionally, particularly after a harsh winter, extreme rainfall or long dry spells.

Signs that there may be a problem with the base include:

Gaps between wall logs

Doors or windows jamming

Uneven floors or cabin sloping

Visible sinking in the corners

If your log cabin is installed on a timber platform, subsidence can sometimes occur. This unlucky customer noticed that the centre of their platform had shrunk, creating a visible gap in the structure. Fortunately, the base was accessible and they were able to reinforce it from underneath to restore balance.

Preventing moisture: Damp Proof Course Damp Proof Membrane

Moisture control is critical to the lifespan of your log cabin so we highly recommend either of the following:

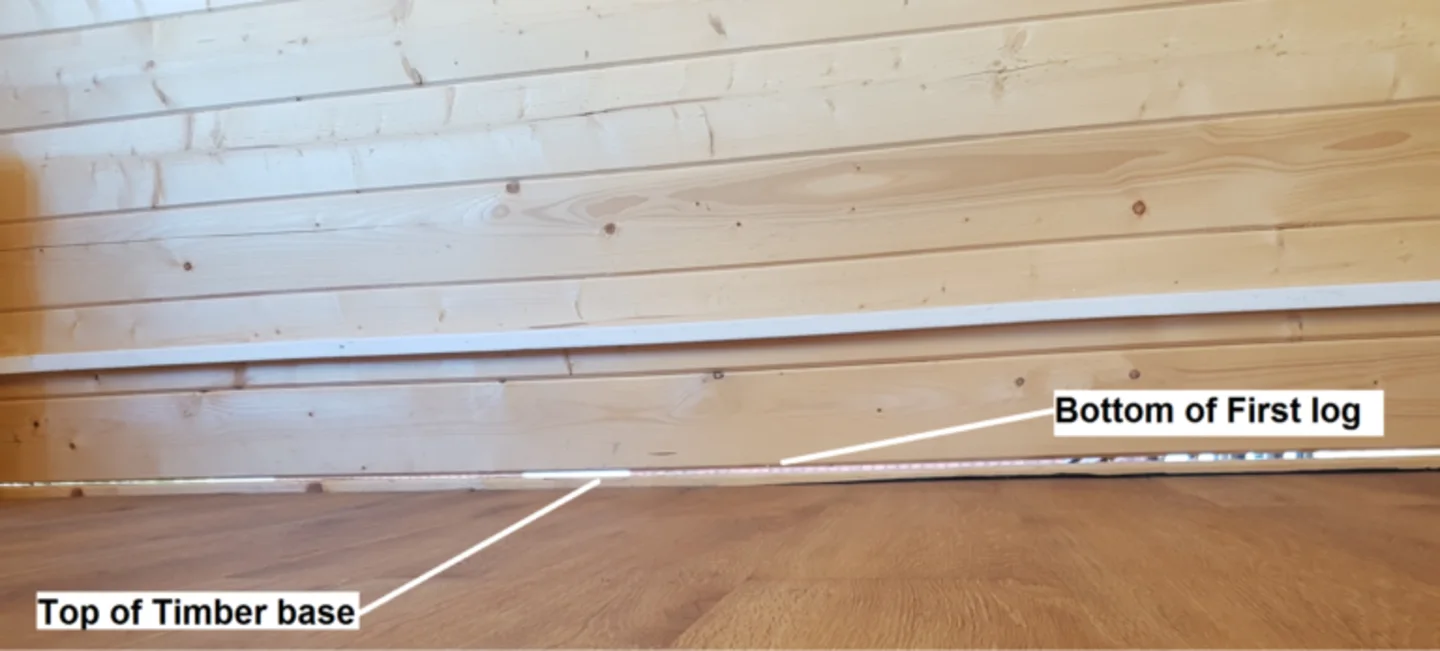

Damp Proof Course (DPC): Installed between the base and the foundation beams, DPC acts as a protective barrier against rising damp from concrete or soil.

Damp Proof Membrane (DPM): A heavy-duty plastic layer laid beneath or on top of concrete slabs to block ground moisture from entering the floor or foundation of your log cabin.

For added protection, many of our customers apply a tar timber treatment to the underside of the foundation beams and directly to the slab surface before installation. This forms a secondary waterproof seal that helps to keep moisture out at the base junctions.

Preventing this moisture from rising up within the building is very important, it can cause unwanted growth inside the building as well as other unwanted issues. If you notice your previously dry and mould free cabin starts to experience these types of problems, a review of your damp proofing may be needed.

2. Foundation beam maintenance

Foundation beams are essential to the functioning of your log cabin. They are designed to:

Lift the wall logs off the ground

Prevent water from being wicked into the timber

Create a gap beneath the cabin for airflow and drainage

Unlike sheds, Tuin log cabins do not use floor bearers that span the entire width of the building. Instead, the beams are placed under perimeter walls and internal partitions only.

A typical shed base with bearers running the same way.

Maintenance tips:

Inspect beams annually for signs of wear, rot or sagging

Apply or reapply sealant at joints between the beams

Ensure the DPC is still effective underneath the beams

Keep the beams free from soil, mulch or debris buildup

At Tuin, we offer a range of foundation beam types, including traditional pressure-treated timber or concrete foundation beams. Whichever you choose, proper installation and sealing are vital to keep water out and maintain structural stability.

You find more on this topic in our blog: Installation tips for log cabins: Foundation beams.

3. Walls: Treatment and moisture management

Once your log cabin has been assembled, treating the walls is key. This is essential just after installation but also regularly throughout the lifespan of your log cabin. Our log cabins are made using interlocking solid wall logs that are designed to resist weather but, like all timber buildings, they need ongoing protection from moisture and UV exposure.

Why timber treatment matters

Timber is a natural material and, left untreated, the wood behaves like a sponge. If you looked at it under a microscope, you’d see a structure full of tiny straws which acts as vessels once used by the tree to transport water. These straws continue to work after the tree is cut, continuing to absorb and release water depending on the humidity and in its surrounding environment. In winter, wood absorbs moisture and swells, in summer it dries out and shrinks.

This ongoing cycle causes the timber to expand and contract, which can weaken joints, crack the surface and distort the structure if not properly treated.

You can find out more about this in our blog: Understanding moisture content in timber.

The role of proper treatment

A quality timber treatment does more than just prevent rot:

It creates a barrier against moisture entering the wood

Limits seasonal movement and warping

Shields the wood from UV rays which cause greying and drying

Helps seal end grain and joints, the most vulnerable parts of your cabin

Provides a decorative finish in your chosen colour or stain

Aim for at least 80-120 microns depth of treatment. This usually needs two to three coats with a brush, or more if using a low viscosity product.

Read more on this in our blog: The best log cabin treatments: Everything you need to know.

Ongoing maintenance

Applying treatment to your log cabin is not a one-time job. Most products need to be applied regularly (every year to five years), depending on weather exposure, product type and location.

Make sure you pay special attention to south-facing walls, interlocking corners and end grain where shrinkage and cracks occur first and touch up any areas where water splashes back from the ground or roof.

4. Doors and windows: Care, treatment and adjustment

Doors and windows are some of the most used parts of your log cabin and often the most affected by changes in the weather and humidity. They’re made from timber so will respond to seasonal moisture and temperature fluctuations in the same way as the walls. However, unlike the logs, doors and windows are not supported on all sides, making them more prone to warping, swelling or twisting if not treated correctly.

How to treat doors and windows properly

Tuin doors and windows are typically made from laminated timber, which helps reduce movement compared to solid wood. However, this doesn’t make them immune to environmental changes so timely and thorough treatment is critical.

Treat all sides evenly

Don’t forget door rebates and window frames

Use the same treatment as the cabin walls to ensure compatibility and performance

If treatment is insufficient or uneven, the timber may warp. Doors could misalign and stick, while windows may no longer sit flush or close properly.

Storage before installation

Doors and windows are packed deep within the log cabin pallet when delivered, held under compression to prevent twisting during transport.

If you’re not installing them immediately, store them flat and under weights, keep them protected from moisture and do not leave them propped upright or unsupported.

Neglecting to do this can lead to premature warping before the cabin has even been built.

Here’s an example of a door that has warped and no longer fits. This door may not have been stored properly prior to installation.

5. Roof maintenance

Your log cabin roof is one of the most crucial elements for long-term weather protection. With proper installation and a little attention throughout the year, your roof can remain in excellent condition for many years to come.

Keep the roof clean

One of the most common causes of roofing issues isn’t the weather, it’s nature. Moss, algae and leaves can build up on the surface, holding moisture and preventing your shingles or roofing material from being able to dry properly. This can lead to rot, mould growth or adhesive failure.

Keep the surface clear, especially on shaded roofs or where overhanging trees drop debris. We recommend using a soft brush or leaf blower and avoid pressure washers as they can damage the roof’s surface and lift the shingles.

Treat and maintain fascia boards

The fascia boards on your cabin roof serve both a decorative and practical function. They finish the edge of your roof and help protect the ends of roof boards from rain and damp. As with any external timbers, the fascia boards are exposed to the elements and require regular retreatment.

It’s not uncommon for birds, wasps or even squirrels to nest in the small gaps under your fascias or roof overhang, which can damage the roofing material and lead to unwanted moisture ingress. Inspect the roofline at least once per season, remove any debris or nests and reseal any small gaps if necessary.

Regular maintenance to preserve your log cabin for years to come

Owning a log cabin is an investment and, like any investment, it’s important to look after it. With ongoing care and maintenance, your log cabin will last for decades, continuing to provide a feature, functionality and shelter in your garden.

Staying ahead of issues with proactive maintenance will allow you to continue enjoying your log cabin.

If you already have a log cabin and need advice on maintaining it or you’re thinking about purchasing a log cabin and need guidance, please contact our expert customer service team.