Ventilation in log cabins

Ventilation is something that is normally overlooked in a Log Cabin. Most of the time though it isn’t necessary. If you’re using it all year round as you’re wandering in and out the air will circulate nicely.

The same applies for garden summer houses and timber garages of course. If opened and used regularly there probably isn’t the need.

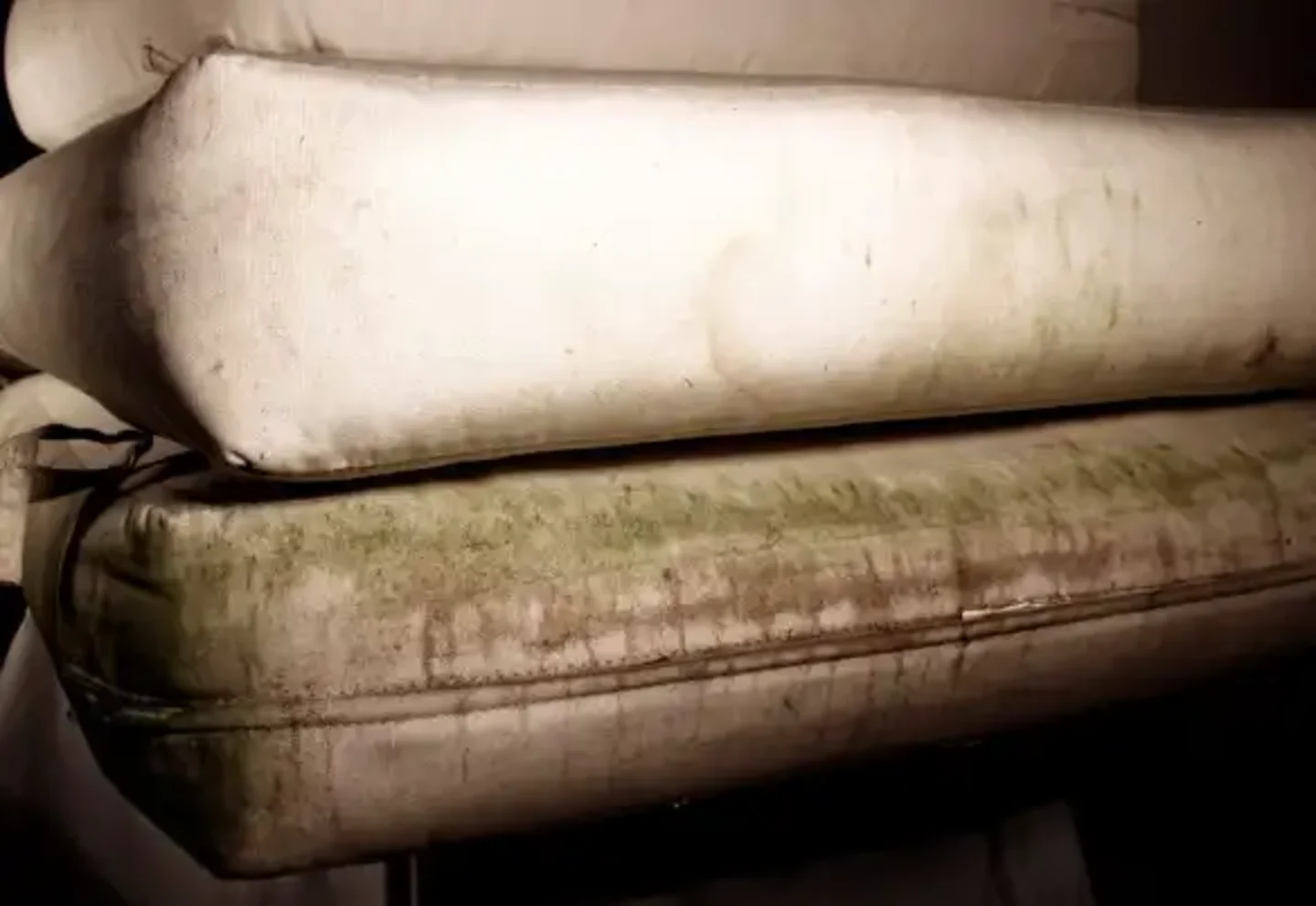

The problem comes if you’re like me and leaves it shut up all the cold months. No doubt like me you’ll end up with your outdoor furniture which you carefully store for the winter looking like this.

I have seen some advice on the net which said: ‘A log cabin ‘breathes’, i.e. ventilation occurs naturally through the timber walls’.

This is true to an extent but also pretty much tosh and please don’t rely on this statement. Wood, pressure and moisture are clever things but they’re also lazy. They want an easy option and the bloomin’ things will take liberties with you and your building.

Basically a log cabin is the same as any other building. It’s an enclosed space and as such, heat and moisture can build up, especially if there is not a damp proof membrane within the base. What normally happens is either damp from the base or damp we introduce in the form of damp furniture, damp tools, etc builds up. This will always create a pressure difference in a log cabin.

Pressure escape

Within a log cabin, there is always a slight pressure difference. The inside is slightly higher than the outside.

As I mentioned earlier, it’s lazy and wants an easy route and the most easiest route is through any gaps, no matter how small. These might be around the windows, the corner connections or even at the join of the roof boards.

I have two garden cabins and one of them is ancient, during the winter it is home to a herd of guinea pigs that live free range all the summer months. Now guinea pigs are only small but you wouldn’t believe the condensation and damp they make. The nearest wall to them is this one:

Effects of not ventilating a log cabin

This is a prime example of a log cabin that isn’t vented. Pressure and moisture being more clever than me have exited from this corner connection, it’s looking for the easiest way out and found it. Coupled of course with me being even more lazy and the back wall has not been treated in a very, very long time so it’s a perfect escape route.

These marks are often associated with water coming in to the cabin. I will occasionally have an old customer write to me asking about this and perhaps complaining their cabins is leaking. The first port of call is of course has it been treated regularly? What with? Etc. But the next question is has it been vented. Invariably the answer is no and then we find our culprit. Especially as it’s left shut up for half a year.

Ventilation

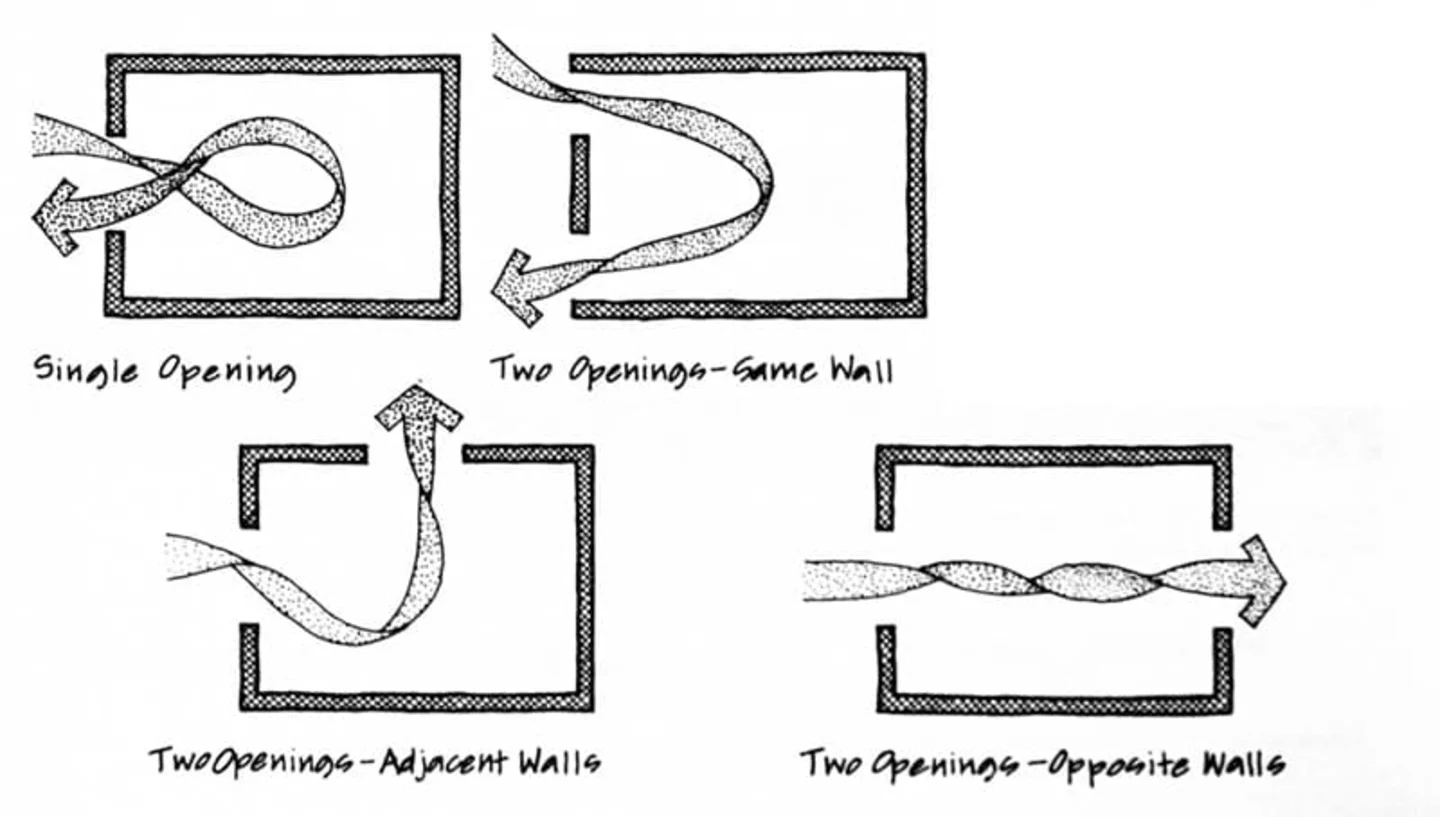

I used to be in the Fire Service, I love a good ventilation lecture and indeed used to give loads but I will not bother here nor will I draw a really good diagram (I did try though). Suffice to say if you are going to keep your log cabins shut up for any longer than a month or two you need ventilation within it.

We supply these for timber buildings.

They’re not flashy or close-able but they do the job nicely. You can also find vents in your local diy shop with all sorts of options.

I could now talk about this sort of ventilation in your log cabin:

We won’t bore you though. I think it’s enough that you should consider some sort of ventilation. Ideally you will have one vent low down and one high up. As I said moisture and pressure is lazy, it’s best to give it an easy route out rather than through your windows or corner connection and possibly causing horrible damp spots.

A shameless plug

I try to be objective in this blog and apply it to all log cabins regardless of manufacturer. But, I will say this, there is a LOT of difference in machining of joints, doors and windows across all suppliers. You may not experience these ventilation problems elsewhere with other manufacturers as the joints are a little looser. Tuindeco provides a high quality product, the joints are extremely tight and pressure will build up within these cabins. A slight downside to the precision machining or perhaps a positive?