Common log cabin problems: Timber movement, contraction, gaps & how to prevent them

When you invest in a log cabin or garden building, you choose the beauty and warmth of natural timber. However, unlike bricks or concrete, wood is a living material, even after it’s been cut and kiln-dried. This means your log cabin will naturally expand and contract throughout the year as temperature and humidity changes. You can find out more about why this happens in our blog: Understanding moisture content in timber.

Many of the common ‘problems’ log cabin owners notice, such as small gaps appearing between logs, minor splits in the wood, or doors and windows sticking, are simply part of how timber behaves. They’re not usually faults with your log cabin, but seasonal movement that every wooden building experiences.

In this guide, we’ll look at the typical issues you might see with your log cabins, explain why they happen and share practical tips on how to prevent or easily fix them. With the right care and understanding, your log cabin will remain strong, secure and aesthetically pleasing for years to come.

Why timber movement is completely natural

Wood is a natural material that warps or moves over time. The material acts as a sponge, so it absorbs and releases moisture depending on the humidity in its surrounding environment. Even after it’s been cut and kiln-dried, wood continues to adjust to its surroundings.

In damp, humid conditions (autumn and winter) timber expands slightly as it takes on more moisture. On the other hand, in hot, dry conditions (such as during a summer heatwave) timber contracts as it loses moisture.

This is why even perfectly built log cabins show signs of seasonal movement. It’s not a fault in the wood, it’s simply how natural materials behave.

Common log cabin problems explained

Many customer concerns we hear are related to these normal seasonal changes. You may notice some of these things as the weather changes throughout the year. Here’s the issues you may experience and why they happen:

1. Gaps between logs

During warm, dry spells (particularly after a heatwave or dry summer), logs can shrink slightly, creating visible, horizontal gaps. This is one of the most common log cabin issues we see, but it’s almost always due to normal contraction.

Is this a problem? What should you do?

This is usually nothing to worry about as the gaps will typically close again when the weather changes and humidity rises. All you need to do is ensure any fascia or corner trims are not fixed too tightly so they can move with the logs.

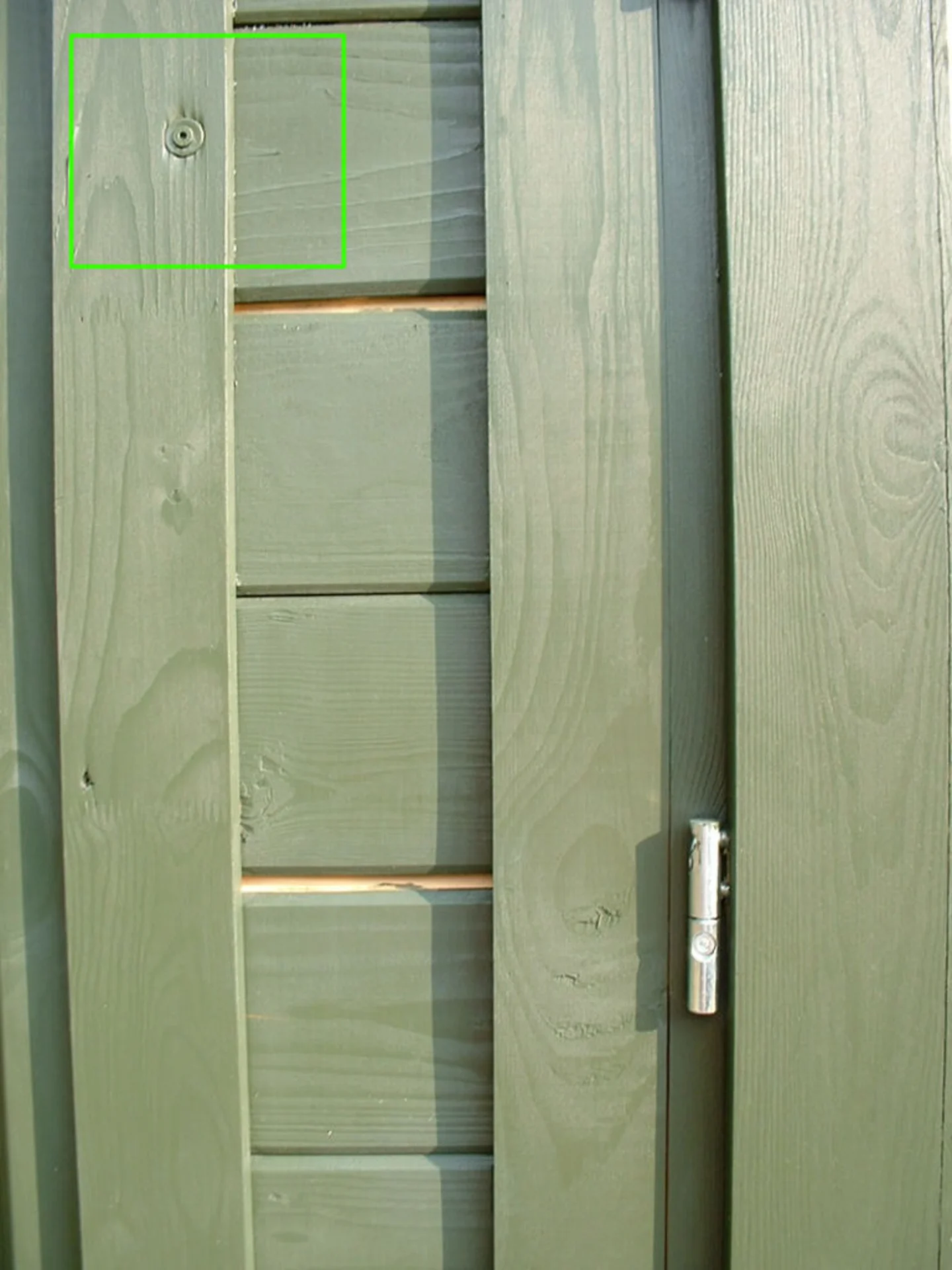

You can see gaps starting to appear between the logs in these images. A log cabin consists of the length of a tree and we pick the best bit close to the heart to build a log cabin. It’s not going to warp as much in its length, but it can change quite a bit in height when part of an install.

The above images are an example of fascia trims being secured too tightly. This will prevent the logs from moving as they should and can cause further problems.

2. Logs appearing to push upwards or bow

In wet or humid conditions, the logs in your log cabin will swell. If doors, windows or fascia boards are fixed too tightly, the expanding logs have nowhere to go and may push upward, causing visible shifting or even small splits.

Is this a problem? What should you do?

This isn’t a problem unless it’s left for too long. To prevent this from happening, check your storm braces and adjust them to allow for movement and make sure screws in corner trims or fascias aren’t over tightened.

3. Doors and windows sticking or misaligning

When the walls of your log cabin expand and contract naturally, door and window frames can become temporarily misaligned. You might notice doors not closing properly in winter, then loosening in the summer.

Is this a problem? What should you do?

This is easily fixed with seasonal maintenance. Tuin’s log cabins use adjustable hinges for exactly this reason, so a quick seasonal tweak of the hinges will solve this problem and still allow for the natural expansion and contraction of the wood.

4. Splits and cracks in the wood

These are small splits that appear as the timber dries. For more information on this, take a look at our blog: Why does timber crack and split? Understanding your timber garden building or fencing.

Is this a problem? What should you do?

These splits and cracks are entirely natural, they’re very common in log cabins and do not weaken the structural integrity of your log cabin.

To minimise the splits and cracks, always treat your log cabin to minimise sudden moisture changes and accept these as part of the natural charm of owning a timber garden building.

Learn more about treating your log cabin here: The best log cabin treatments: Everything you need to know.

How to prevent and manage these issues

Owning a log cabin means accepting some natural timber behaviour. However, you can take steps to protect your log cabin and minimise the effect of these changes.

During installation: Allow logs to settle after installation and make sure you don’t over-tighten storm braces or fix trims tightly across logs. Make sure you also follow expansion gaps guidance when installing your log cabin. Tuin cabins are designed with clear allowances for timber movement.

Treatment is key: Use a good quality wood treatment inside and outside to help regulate moisture absorption and keep your log cabin protected from the elements. Make sure you reapply treatments regularly (annually is recommended and required for Tuin’s guarantee) to protect against water ingress and UV damage.

Keep water away: Ensure your roof is well covered with felt or shingles, add guttering to carry water away from your log cabin walls and ensure your log cabin is elevated on a well-built base to prevent rising damp.

Seasonal maintenance: Seasonal adjustments to hinges on doors and windows, if needed, will ensure they continue to fit well. You can also tighten or loosen storm braces to accommodate timber movement.

What’s normal and when should you be concerned?

Timber is a natural material, so some changes are just part of owning a wooden building. These include:

Small gaps that open and close with the seasons

Minor splits or cracks

Doors and windows needing the occasional tweak

Storm braces loosening or tightening slightly

When to investigate further

Most issues are harmless and a natural part of wood movement, but there are times when it might be worth taking a closer look or getting in touch with our team for support.

Large gaps that don’t close up after damp weather: Persistent, wide gaps could indicate an installation issue (such as trims or frames fixed too tightly) that are preventing logs from settling properly.

Logs twisting or bowing significantly: A slight curve is common in natural wood, but pronounced twisting may require adjustment or indicate a moisture imbalance.

Water ingress that continues despite effective treatment and roofing: If you see damp patches inside your log cabin, check your roof covering, guttering and treatment. Persistent leaks could suggest damage to your roofing, a gutter blockage or that your log cabin needs extra coats of treatment.

Talk to our customer service team

At Tuin, we’re always happy to help if you have an issue with your log cabin. If you’re unsure whether something is normal or not, contact our team, send us a quick photo and a description. Our experts can usually identify a problem and advise you on potential tweaks. We’ll even come out to inspect your log cabin if it’s something more major.

Browse our full range of log cabins today to build your dream garden escape.